Safety Silver S20 – Security Window Film

A silver reflective 8 mil (.008”) security film that is made of PET polyester.

Safety Silver S20 Security Window Film – Features & Benefits:

- Combination safety / solar control window film

- Help protect from broken glass hazards

- Increase privacy, reduce glare and eye discomfort

- Increase comfort and help reduce air conditioning costs

- Helps extend the life of furnishings by significantly reducing harmful UV rays Applications

- Bomb Blast Mitigation

- Building Envelope Protection

- Helping to Deter Break & Entry

- Safety Glazing

- Seismic Preparedness

- Spontaneous Glass Breakage

Safety Silver S20 – Safety Series – Security Window Film

Safety Silver S20 – Security Window Film – Performance Results:

1.1 SECTION INCLUDES

A. Safety and security films.

1.2 RELATED SECTIONS

A. Section 08500 – Windows; windows to receive architectural window film.

B. Section 08600 – Skylights; glass skylights to receive architectural window film.

C. Section 08800 – Glazing; general glazing applications to receive architectural window film.

D. Section 08900 – Glazed Curtain Walls; curtain walls to receive architectural window film.

1.3 REFERENCES

A. ASHRAE – American Society for Heating, Refrigeration, and Air Conditioning Engineers; Handbook of Fundamentals.

B. ASTM International (ASTM):

1. ASTM D 882 – Standard Test Method for Tensile Properties of Thin Plastic Sheeting.

2. ASTM D 1044 – Standard Method of Test for Resistance of Transparent Plastics to Surface Abrasion (Taber Abrader Test).

3. ASTM D 4830 – Standard Test Methods for Characterizing Thermoplastic Fabrics Used in Roofing and Waterproofing.

4. ASTM E 84 – Standard Method of Test for Surface Burning Characteristics of Building Materials.

5. ASTM E 903 – Standard Methods of Test for Solar Absorbance, Reflectance and Transmittance of Materials Using Integrating Spheres.

6. ASTM E 1886 – Standard Test Method for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed to Cyclic Pressure Differentials.

7. ASTM E 1996 – Standard Specification for Performance of Exterior Windows, Curtain Walls, Doors and Impact Protective Systems Impacted by Windborne Debris in Hurricanes.

8. ASTM F1642 – Standard Method of Test for Glazing and Glazing Systems Subject to Airblast Loadings

C. ANSI Z97.1 – American National Standard for Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test.

D. Consumer Products Safety Commission 16 CFR, Part 1201 – Safety Standard for Architectural Glazing Materials.

E. GSA-TS01-2003 — Standard Test for Glazing and Glazing Systems Subject to Airblast Loadings.

F. NFRC 100/200 (Formerly ASTM E903) – Standards Methods of Test for Solar Absorbance, Reflectance, and Transmittance of Materials Using Integrating Spheres.

1.4 PERFORMANCE REQUIREMENTS

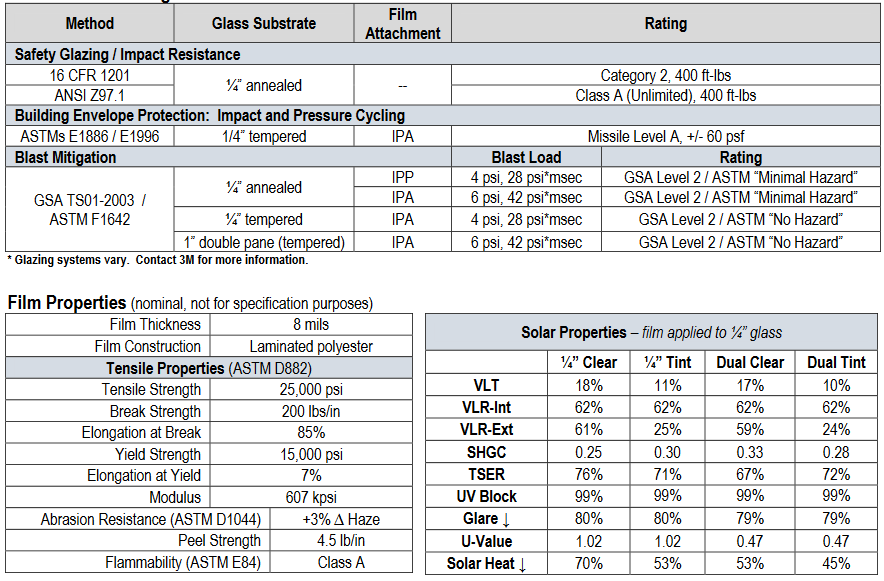

A. Safety Glazing Impact Performance: 400 ft-lbs impact resistance, meeting ANSI Z97.1 (Class A, Unlimited) impact requirements with film applied on ¼” annealed glass.

B. Blast Hazard Mitigation Performance

ASTM F1642 “Minimal Hazard” and GSA TS01-2003 “Level 2” at minimum blast load of 6 psi and 42 psi*msec. Glazing systems vary, contact Manufacturer for more information.

C. Missile Impact and Pressure Cycling for Building Envelope Protection:

ASTM E1886 / E1996 Small Missile A Impact resistance and subsequent pressure cycling +/- 60 psf Design Pressure. Glazing systems vary, contact Manufacturer for more information.

D. Flammability Performance: Surface burning characteristics when tested in accordance ASTM E 84, demonstrating film applied to glass rated Class A for Interior Use:

1. Flame Spread Index: < 5

2. Smoke Developed Index: < 25

E. Optical / Solar Properties (filmed applied to ¼” clear single pane glass 1. Solar Heat Gain Coefficient:

Not more than 0.25

2. Visible Light Transmission: not more than 18%

3. Visible Light Reflected (Interior): not more than 62%

4. Visible Light Reflected (Exterior): not more than 61%

1.5 SUBMITTALS

A. Submit under provisions of Section 01300.

B. Product Data: Manufacturer’s current technical literature on each product to be used, including:

1. Manufacturer’s Data Sheets

2. Preparation instructions and recommendations

3. Storage and handling requirements and recommendations

4. Installation methods

C. Verification Samples: For each film specified, two samples representing actual film color and pattern

D. 3rd Party Test Report Submittal Requirements. Submit the following 3rd Party test reports indicating compliance with the test values listed in this section.

1. Flammability Testing, ASTM E84

2. Safety Glazing Impact Testing, 16 CFR 1201

3. Missile Impact and Pressure Cycling Testing, ASTMs E1886/E1996

4. Blast Hazard Mitigation Testing, ASTM F1642 / F2912 and/or GSA-TS01-2003

E. Other Product Submittal

1. Manufacturer’s summary of 3rd Party Blast Hazard Mitigation Testing, ASTM F1642 / F2912 and/or GSA-TS01-2003

F. Installer Qualifications: Submit the following documentation:

1. Provide documentation, including Manufacturer assigned Dealer number, which verifies the installer is authorized by the Manufacturer to perform Work specified in this section.

2. Provide a commercial building reference list of 5 properties where the installer has applied window film. This list will include the following information:

a. Name of building.

b. The name and telephone number of a management contact.

c. Type of glass.

d. Type of film.

e. Amount of film installed.

f. Date of completion.

1.6 QUALITY ASSURANCE

A. Manufacturer Qualifications: All primary products specified in this section will be supplied by a single manufacturer with a minimum of ten years experience.

B. Installer Qualifications: All products listed in this section are to be installed by a single installer with a minimum of five years demonstrated experience in installing products of the same type and scope as specified.

C. Mock-Up: Provide a mock-up for evaluation of surface preparation techniques and application workmanship.

1. Finish areas designated by Specifying Authority.

2. Do not proceed with remaining work until workmanship, color, and sheen are approved by the Specifying Authority.

3. Refinish mock-up area as required to produce acceptable work.

D. Provide a Glass Stress Analysis of the existing glass and proposed glass/film combination as recommended by the film manufacturer.

1.7 DELIVERY, STORAGE, AND HANDLING

A. Store products in manufacturer’s unopened packaging until ready for installation.

B. Store and dispose of hazardous materials, and materials contaminated by hazardous materials, in accordance with requirements of local authorities having jurisdiction.

1.8 PROJECT CONDITIONS

A. Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer’s absolute limits.

1.9 WARRANTY

A. At project closeout, provide to Owner or Owners Representative an executed current copy of the manufacturer’s standard limited warranty against manufacturing defect, outlining its terms, conditions, and exclusions from coverage.

B. For warranty to be valid, product must have been installed by a Manufacturer Authorized Dealer/Applicator according to Manufacturer’s installation instructions

PART 2 PRODUCTS

2.1 MANUFACTURERS

A. Acceptable Manufacturer: 3M Window Film , which is located at: 3M Center Bldg. 0235-02-S-27 ; St. Paul, MN 55144-1000; Toll Free Tel: 800-480-1704; Tel: 651-733-2222; Fax: 651-737-3446; Web: www.3m.com/windowfilm

B. Requests for substitutions will be considered in accordance with provisions of Section 01600.

2.2 SAFETY AND SECURITY WINDOW FILM WITH SUN CONTROL

A. Safety and Security Window Film with Sun Control: 3M™ Safety Series, Silver S20. Highly reflective polyester film, nominally 8 mils (0.008”) thick, with a durable abrasion resistant coating over one surface and a pressure sensitive adhesive on the other. The film is comprised of an optically clear safety film laminated to a metallized film layer for reflective and sun control properties. The adhesive is pressure-activated, not water-activated, and forms a mechanical bond, not chemical bond, to the glass.

1. Physical / Mechanical Performance Properties (nominal):

a. Film Color: Silver reflective

b. Film Thickness (excluding coatings or adhesive liner): Nominal 8 mils

c. Tensile Properties, with coatings (ASTM D882):

1) Tensile Strength: 20,000 psi (MD) / 30,000 psi (TD)

2) Break Strength: 160 lb/in (MD) / 247 lb/in (TD)

3) Percent Elongation at Break: 95 % (MD) / 76 % (TD)

4) Yield Strength: 15,000 psi

5) Percent Elongation at Yield: 7%

6) Young’s Modulus: 560 kpsi (MD) / 650 kpsi (TD)

2. Uniformity: No noticeable pin holes, streaks, thin spots, scratches, banding or other optical defects.

3. Variation in Total Transmission across the width: Less than 2 percent over the average at any portion along the length.

4. Identification: Labeled as to Manufacturer as listed in this Section.

5. Solar Performance Properties: Film applied to 1/4 inch (6.4 mm) thick clear glass (NFRC 100/200).

a. Visible Light Transmission: 18%

b. Visible Reflection: 61%

c. Ultraviolet Transmission: Not more than 1%.

d. Solar Heat Gain Coefficient: 0.25

6. Impact Resistance for Safety Glazing: Tested on 1/4 inch (6.4 mm) annealed glass.

a. Safety Rating (CPSC 16 CFR, Part 1201): Category 2 (400 ft-lbs).

b. Safety Rating (ANSI Z97.1): Class A, Unlimited (400 ft-lbs).

7. Building Envelope Protection: Missile Impact and Pressure Cycling Film shall pass impact of Small Missile “A” and withstand subsequent pressure cycling (per ASTMs E1996 and E1886) at +/- 60 psf Design Pressure with use of 3M Impact Protection Adhesive attachment system. Tested on ¼” tempered glass.

8. Bomb Blast Mitigation: Independent testing with results from high explosive arena blast or shock tube testing.

a. GSA Rating of “2” / ASTM F1642 “Minimal Hazard” with blast pressure of 4 psi and 28 psi*msec blast impulse, on ¼” annealed single pane glass and 3M Impact Protection Profile Attachment system

b. GSA Rating of “2”/ ASTM F1642 “Minimal Hazard” with blast pressure of 6 psi and 42 psi*msec blast impulse, on ¼” annealed single pane glass and 3M Impact Protection Adhesive Attachment system

c. GSA Rating of “2” / ASTM F1642 “No Hazard” with blast pressure of 4 psi and 28 psi*msec blast impulse, on ¼” tempered single pane glass and 3M Impact Protection Adhesive Attachment system

d. GSA Rating of “2” / ASTM F1642 “No Hazard” with blast pressure of 6 psi and 42 psi*msec blast impulse, on 1” double pane tempered glass and 3M Impact Protection Adhesive Attachment system

PART 3 EXECUTION

3.1 EXAMINATION

A. If preparation of glass surfaces is the responsibility of another installer, notify Specifier in writing of deviations from manufacturer’s recommended installation tolerances and conditions.

1. Glass surfaces receiving new film should first be examined to verify that they are free from defects and imperfections, which will affect the final appearance:

B. Do not proceed with installation until glass surfaces have been properly prepared and deviations from manufacturer’s recommended tolerances are corrected. Prepare surfaces using the methods recommended by the manufacturer for achieving the best result under the project conditions.

C. Commencement of installation constitutes acceptance of conditions.

3.2 PREPARATION

A. Clean surfaces thoroughly prior to installation.

B. Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions.

C. Refer to Manufacturer’s installation instructions for methods of preparation of film attachment systems.

3.3 INSTALLATION

A. Install in accordance with manufacturer’s instructions.

B. Cut film edges neatly and square at a uniform distance of 1/8 inch (3 mm) to 1/16 inch (1.5 mm) of window sealant. Use new blade tips after 3 to 4 cuts.

C. Spray the slip solution, composed of 1 capful of baby shampoo or dishwashing liquid to 1 gallon of water, on window glass and adhesive to facilitate positioning of film.

D. Apply film to glass and lightly spray film with slip solution.

E. Squeegee from top to bottom of window, using a security film squeegee no wider than 5 inches. Apply firm pressure with squeegee to maximize effectiveness of slip solution removal. Spray slip solution to film as needed to reduce squeegee friction.

F. Bump film edges with a lint-free towel wrapped around edge of a 5-way tool.

G. Upon completion of film application, allow 30 days for moisture from film installation to dry thoroughly, and to allow film to dry flat with no moisture dimples when viewed under normal viewing conditions.

3.4 CLEANING AND PROTECTION

A. Remove left over material and debris from Work area. Use necessary means to protect film before, during, and after installation.

B. Touch-up, repair or replace damaged products before Substantial Completion.

C. After application of film, wash film using common window cleaning solutions, including ammonia solutions, 30 days after application. Do not use abrasive cleaners or brushes to avoid scratching film. Use only synthetic sponges or soft cloths.