Enhancing light as only 3M can; Night Vision 25 – Sun Control Window Films

Known as Night Vision because the reflectivity commonly associated with window film has been greatly reduced, inside and outside, day and night. This is the darkest version with a 25% light transmission.

Night Vision 25 Benefits:

- Great heat rejection provides energy savings and improved comfort

- A warm natural hue invites warmth and beauty to any room

- Extends the life of furnishings by significantly reducing UV rays, the largest cause of fading

- Low interior and exterior reflectivity, especially at night!

- New 3M nano-technology enhances color stability

- Reduces glare and eye discomfort

- Comprehensive 3M manufacturer’s warranty

- Increases personal safety from flying glass

- Superior scratch resistant coating

Night Vision 25 – Sun Control Window Films

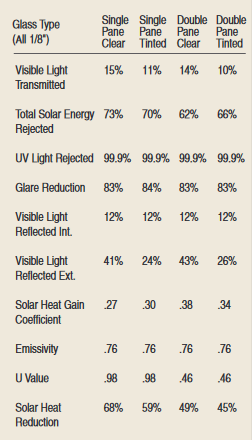

Performance data generated for a typical film on 3mm glass using applicable industry test methods and standards.

3M Sun Control Window Films

Performance Results:

Visible Light Transmitted – 15%

Total Solar Energy Rejected – 73%

UV Light Rejected – 99.9%

Glare Reduction – 83%

Visible Light Reflected Interior – 12%

Visible Light Reflected Exterior – 41%

Solar Heat Reduction – 68%

PART 1 – GENERAL

1.1 SUMMARY

A. Section Includes:

1. Abrasion-resistant, solar control, reflective window film. Film is designed to reduce gain of solar heat energy through window by reflecting more to the exterior than interior. Traditional metalized films reflect equally both inside and outside, where you need it, and less to the inside. The Night Vision line reflects more to the outside, where you need it, and less to the inside, where you do not need it. 3M Night Vision, carbon impregnated polyester layer provides outstanding heat rejection performance.

1.2 SYSTEM DESCRIPTION

A. Performance Requirements:

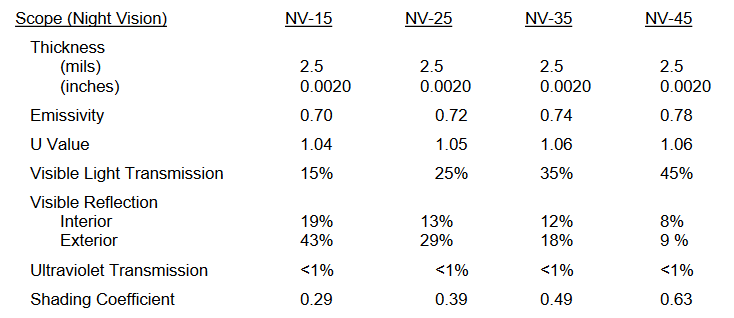

1. Provide reflective films that comply with the following:

B. Film Attributes: The following attribute information is based upon 1/4 inch (6 mm) clear glass unless indicated otherwise:

1. Adhesive System: Pressure sensitive, weatherable, acrylate adhesive applied uniformly over surface opposite abrasion resistant coated surface.

a. Viewing film from a distance of 10 feet (3 m) at angles up to 45 degrees from either side of glass, film shall not appear distorted.

2. Flammability: Class A Interior Finish for Buildings Materials for both Flame Spread Index and Smoke Development Values per ASTM E84.

3. Abrasion Resistance: Surface coating resistant to abrasion, with less than 5 percent increase of transmitted light haze resulting per ASTM D1044 using 100 cycles, 500 grams of weight, and CS10F Calbrase Wheel.

1.3 SUBMITTALS

A. Product Data: Manufacturer’s product data including installation instructions and cleaning methods.

B. Warranty: Manufacturer’s standard limited warranty indicating warranty coverage.

1.4 DELIVERY, STORAGE, AND HANDLING

A. Manufacturer will ensure proper quality control during production, shipping, and inventory, clearly identify and label each film core with product designation and run number.

B. Deliver materials to Project site with manufacturer’s labels intact and legible.

1.5 QUALITY ASSURANCE

A. Dealer and Applicator Qualifications: Provide documentation that dealer and applicator are authorized by manufacturer of window film to install window films.

1. Provide reference list of 5 projects of similar size on which applicator has installed window films. Include on the list the following:

a. Name of building.

b. Name and telephone number of management contact.

c. Type of glass.

d. Type of film.

e. Amount of film installed.

f. Date of completion.

1.6 WARRANTY

A. Warrant materials and workmanship for 12 years against defects after completion and final acceptance of Work.

1. Repair defects from faulty materials or workmanship developed during guarantee period, or replace with new materials, at no expense to Owner.

2. Warranty covers the following:

a. Film will maintain solar reflective properties without cracking, crazing, delaminating, peeling, or discoloration.

b. Glass failure due to thermal shock fracture of glass (maximum value $500.00 per window) provided film is applied to recommended types of glass and failure occurs within 60 months from start of application. Glass failures shall reviewed by film manufacturer prior to replacement.

PART 2 – PRODUCTS

2.1 MANUFACTURER

A. Subject to compliance with requirements, provide products from f the following manufacturer:

1. 3M Company

2. Distributed through: GlassEnergy

3. Point of Contact: Rob Versa, 1-877-684-4040, info@glassenergy.com

2.2 MATERIALS

A. Film Material: Film material consists of an optically clear metallized polyester film which may be laminated to a clear polyester film. Provide films with acrylic abrasion-resistant coating over surface of film for enhanced durability.

1. Film Color: Derived from metal coating and/or components, and product will not contain conventional dyed polyester.

2. Provide uniform film, without noticeable pin holes, streaks, thin spots, scratches, banding, or other optical defects. Variation in total transmission across width, at any portion along length, shall not exceed 2 percent over average. Density of film across web is not to exceed plus or minus 2 percent. Provide film with no evidence of coating voids.

B. Acceptable Products:

3M TM Sun Control Window Films.

1. 3M Night Vision NV-15

2. 3M Night Vision NV-25

3. 3M Night Vision NV-35

4. 3M Night Vision NV-45

PART 3 – EXECUTION

3.1 EXAMINATION

A. Examine glass surfaces to receive film and verify that they are free from defects and imperfections, which will affect final appearance. Correct and note such deficiencies to [Owner] [Architect] prior to commencing film application.

3.2 PREPARATION

A. Use protective tarps and drop cloths to cover interior finishes near window.

B. Turn off or cover heating and air conditioning ventilation ducts.

C. Clean window and window framing thoroughly with cleaning solution consisting of 90 percent water and 10 percent ammonia. Blade inside surface of window glass with industrial razors to insure removal of foreign contaminants. 1. Tape and seal cracked and deteriorating window sealant.

D. Place towel or other absorbent material on window sill or sash to absorb moisture accumulation generated by film application.

E. Thoroughly rinse glass from top to bottom with pressure spray tank.

F. Squeegee entire glass surface.

G. Dry glass edges and window frames using a lint-free towel.

3.3 INSTALLATION

A. Install window films per manufacturer’s written instructions.

1. Cut film edges neatly and square at a uniform distance of 1/8 inch (3 mm) to 1/16 inch (1.5 mm) of window sealant. Use new blade tips after 3 to 4 cuts.

2. Spray slip solution, composed of one capful of Johnson® Baby Shampoo or Joy® Dish washing Liquid to 1 gallon of water, on window glass and adhesive to facilitate proper positioning of film.

3. Apply film to glass and lightly spray film with slip solution.

4. Squeegee to remove water. Squeegee from top to bottom of window.

5. Spray slip solution to film and squeegee a second time.

6. Bump film edge with lint-free towel wrapped around edge of a 5-way tool.

7. Wipe frame edge dry

8. Inspect installation to insure proper application.

9. Upon completion of film application, allow 30 days for moisture from film installation to dry thoroughly, and to allow film to dry flat with no moisture dimples when viewed under normal viewing conditions.

3.4 CLEANING

A. After application of film, wash film using common window cleaning solutions, including ammonia solutions, 30 days after application. Do not use abrasive type cleaning agents and bristle brushes to avoid scratching film. Use synthetic sponges or soft cloths.

B. After installation, remove left over material and debris from Work area. Use necessary means to protect film before, during, and after installation.

END OF SECTION